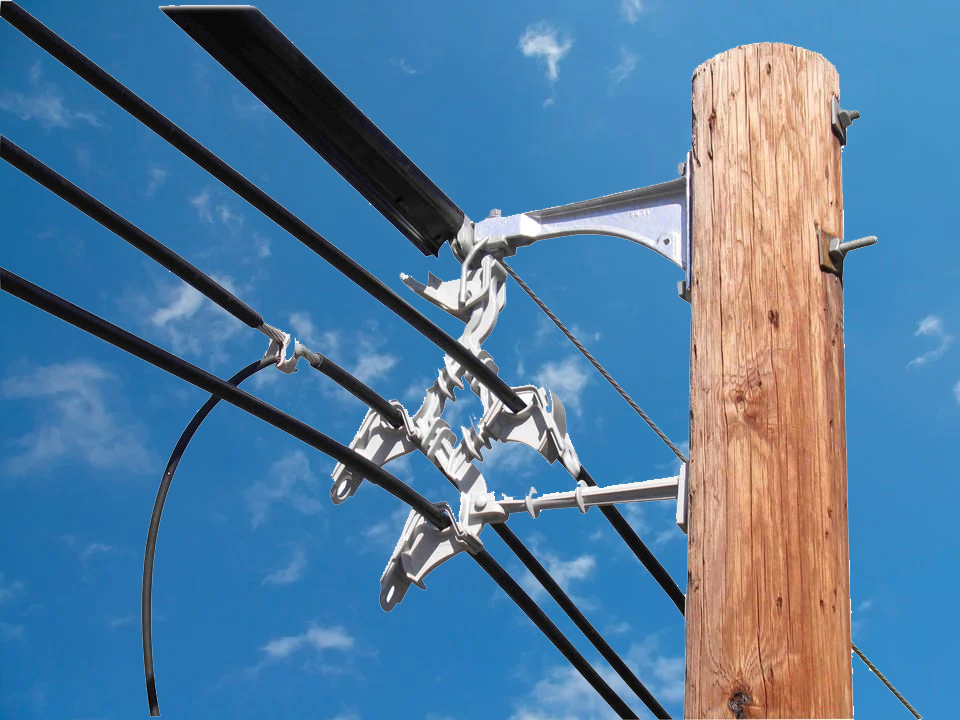

Medium voltage aerial bundled cables are mainly used for secondary overhead lines on poles or as feeders to residential premises.

Standard:

AS/NZS 3599---Electric cables—Aerial bundled— Polymeric insulated—Voltages 6.3511 (12) kV and 12.722 (24) kV

Voltage:

6.6kV-22kV

Construction:

Conductor Screen: Extruded semi-conductive layer.

Insulation: XLPE.

Insulation Screen: Extruded semi-conductive layer.

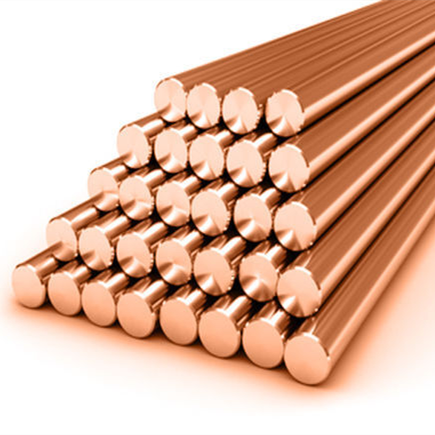

Metallic Screen(optional): Copper wire screen or copper tape screen.

Separator: Semi-conductive swellable tape.

Outer Sheath: HDPE.

Support Conductor: Galvanized steel wires.

Assembly Three XLPE insulated screened cores are bundled around the galvanized steel wires in a right hand lay.

Why Choose Us?

We produce quality cables by using high-end material:

Rich experience team knowing what's your demand:

Plant with good facilities and capacity to guarantee on-time delivery:

AS/NZS 3599 part 1 6.35/11kV AL/XLPE/HDPE non-screened cables

|

Number of Cores x Nominal Cross Section |

Phase Conductor |

Messenger Suspension Unit |

Nominal Sectional Area |

Breaking Load |

|||

|

Diameter of Conductor |

Thickness of Insulation |

Thickness of Insulation Screen |

Thickness of Sheath |

Stranding |

|||

|

No.×mm² |

mm |

mm |

mm |

mm |

No.×mm |

mm² |

kN |

| 3×35 | 6.9 | 3.4 | 0.8 | 1.2 | 7/4.75 | 52.4 | 1370 |

| 3×50 | 8.1 | 3.4 | 0.8 | 1.2 | 7/4.75 | 54.6 | 1530 |

| 3×70 | 9.7 | 3.4 | 0.8 | 1.2 | 7/4.75 | 57.8 | 1790 |

| 3×95 | 11.4 | 3.4 | 0.8 | 1.2 | 7/4.75 | 61.3 | 2100 |

| 3×120 | 12.8 | 3.4 | 0.8 | 1.2 | 19/3.50 | 67.3 | 2540 |

| 3×150 | 14.2 | 3.4 | 0.8 | 1.2 | 19/3.50 | 70.1 | 2840 |

| 3×185 | 15.7 | 3.4 | 0.8 | 1.2 | 19/3.50 | 73.1 | 3190 |

AS/ZNS 3599 part 1 6.35/11kV AL/XLPE/CWS/HDPE screened cables

|

Number of Cores x Nominal Cross Section |

Diameter of Conductor |

Thickness of Insulation |

Thickness of Insulation Screen |

Copper Wire Screen Stranding |

Thickness of Sheath |

Galvanized Steel Wire Stranding |

Nominal Sectional Area |

Breaking Load |

|

No.×mm² |

mm |

mm |

mm |

No.×mm |

mm |

No.×mm |

mm² |

kN |

| Light duty screen | ||||||||

| 3×35 | 6.9 | 3.4 | 0.8 | 25/0.85 | 1.8 | 7/2.00 | 54.1 | 1820 |

| 3×35 | 6.9 | 3.4 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 58.1 | 2130 |

| 3×50 | 8.1 | 3.4 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 60.4 | 2300 |

| 3×70 | 9.7 | 3.4 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 63.6 | 2570 |

| 3×95 | 11.4 | 3.4 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 67.0 | 2900 |

| 3×120 | 12.8 | 3.4 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 69.8 | 3190 |

| 3×150 | 14.2 | 3.4 | 0.8 | 25/0.85 | 1.9 | 19/2.00 | 73.0 | 3530 |

| 3×185 | 15.7 | 3.4 | 0.8 | 25/0.85 | 1.9 | 19/2.00 | 76.0 | 3890 |

| Heavy duty screen | ||||||||

| 3×35 | 6.9 | 3.4 | 0.8 | 40/0.85 | 1.8 | 7/2.00 | 54.1 | 2050 |

| 3×35 | 6.9 | 3.4 | 0.8 | 40/0.85 | 1.8 | 19/2.00 | 58.1 | 2360 |

| 3×50 | 8.1 | 3.4 | 0.8 | 23/1.35 | 1.8 | 19/2.00 | 62.4 | 2820 |

| 3×70 | 9.7 | 3.4 | 0.8 | 32/1.35 | 1.8 | 19/2.00 | 65.6 | 3440 |

| 3×95 | 11.4 | 3.4 | 0.8 | 39/1.35 | 1.8 | 19/2.00 | 69.0 | 4030 |

| 3×120 | 12.8 | 3.4 | 0.8 | 39/1.35 | 1.8 | 19/2.00 | 71.8 | 4320 |

| 3×150 | 14.2 | 3.4 | 0.8 | 39/1.35 | 1.9 | 19/2.00 | 75.0 | 4670 |

| 3×185 | 15.7 | 3.4 | 0.8 | 39/1.35 | 1.9 | 19/2.00 | 78.0 | 5020 |

AS/NZS 3599 part 1 12.7/22kV AL/XLPE/HDPE non-screened cables

|

Number of Cores x Nominal Cross Section |

Phase Conductor |

Messenger Suspension Unit |

Nominal Sectional Area |

Breaking Load |

|||

|

Diameter of Conductor |

Thickness of Insulation |

Thickness of Insulation Screen |

Thickness of Sheath |

Stranding |

|||

|

No.×mm² |

mm |

mm |

mm |

mm |

No.×mm |

mm² |

kN |

| 3×35 | 6.9 | 5.5 | 0.8 | 1.2 | 7/4.75 | 61.0 | 1780 |

| 3×50 | 8.1 | 5.5 | 0.8 | 1.2 | 7/4.75 | 63.3 | 1970 |

| 3×70 | 9.7 | 5.5 | 0.8 | 1.2 | 7/4.75 | 66.5 | 2260 |

| 3×95 | 11.4 | 5.5 | 0.8 | 1.2 | 7/4.75 | 69.9 | 2600 |

| 3×120 | 12.8 | 5.5 | 0.8 | 1.2 | 19/3.50 | 75.9 | 3070 |

| 3×150 | 14.2 | 5.5 | 0.8 | 1.2 | 19/3.50 | 78.7 | 3390 |

| 3×185 | 15.7 | 5.5 | 0.8 | 1.2 | 19/3.50 | 81.7 | 3760 |

AS/NZS 3599 part 1 12.7/22kV AL/XLPE/CW/HDPE screened cables

|

Number of Cores x Nominal Cross Section |

Diameter of Conductor |

Thickness of Insulation |

Thickness of Insulation Screen |

Copper Wire Screen Stranding |

Thickness of Sheath |

Galvanized Steel Wire Stranding |

Nominal Sectional Area |

Breaking Load |

|

No.×mm² |

mm |

mm |

mm |

No.×mm |

mm |

No.×mm |

mm² |

kN |

| Light duty screen | ||||||||

| 3×35 | 6.9 | 5.5 | 0.8 | 25/0.85 | 1.8 | 7/2.00 | 62.7 | 2280 |

| 3×35 | 6.9 | 5.5 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 66.7 | 2580 |

| 3×50 | 8.1 | 5.5 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 69.0 | 2780 |

| 3×70 | 9.7 | 5.5 | 0.8 | 25/0.85 | 1.9 | 19/2.00 | 72.6 | 3110 |

| 3×95 | 11.4 | 5.5 | 0.8 | 25/0.85 | 1.9 | 19/2.00 | 76.0 | 3460 |

| 3×120 | 12.8 | 5.5 | 0.8 | 25/0.85 | 2.0 | 19/2.00 | 79.2 | 3810 |

| 3×150 | 14.2 | 5.5 | 1.0 | 25/0.85 | 2.0 | 19/2.00 | 82.8 | 4230 |

| 3×185 | 15.7 | 5.5 | 1.0 | 25/0.85 | 2.1 | 19/2.00 | 86.2 | 4650 |

| Heavy duty screen | ||||||||

| 3×35 | 6.9 | 5.5 | 0.8 | 40/0.85 | 1.8 | 7/2.00 | 62.7 | 2510 |

| 3×35 | 6.9 | 5.5 | 0.8 | 40/0.85 | 1.8 | 19/2.00 | 66.7 | 2810 |

| 3×50 | 8.1 | 5.5 | 0.8 | 23/1.35 | 1.8 | 19/2.00 | 71.0 | 3300 |

| 3×70 | 9.7 | 5.5 | 0.8 | 32/1.35 | 1.9 | 19/2.00 | 74.6 | 3970 |

| 3×95 | 11.4 | 5.5 | 0.8 | 39/1.35 | 1.9 | 19/2.00 | 78.0 | 4600 |

| 3×120 | 12.8 | 5.5 | 0.8 | 39/1.35 | 2.0 | 19/2.00 | 81.2 | 4950 |

| 3×150 | 14.2 | 5.5 | 1.0 | 39/1.35 | 2.0 | 19/2.00 | 84.8 | 5360 |

| 3×185 | 15.7 | 5.5 | 1.0 | 39/1.35 | 2.1 | 19/2.00 | 88.2 | 5790 |

Technical data

|

Nominal Cross Section |

Continuous Current Rating |

||

|

Still Air |

1m/s wind |

2m/s wind |

|

| mm² | A | A | A |

| 35 | 105 | 145 | 165 |

| 50 | 125 | 170 | 200 |

| 70 | 150 | 215 | 250 |

| 95 | 180 | 260 | 300 |

| 120 | 205 | 300 | 350 |

| 150 | 230 | 340 | 395 |

| 185 | 265 | 390 | 450 |

More Product

Send An Email

Send An Email