XLPE insulated power cable has a number of advantages over paper insulated and PVC insulated cable. XLPE cable has high electric strength, mechanical strength, high-ageing resistance, environmental stress resisting anti-chemical corrosion, and it is simple construction, using convenient and higher operating of long term temperature. It can be laid with no drop restriction. Various of flame-retardant and non-flame retardant XLPE cable can be manufactured with three technologies(peroxide,silence,and irradiation cross linking).The flame-retardant cable covers all kinds of low- smoke,low-halogen,low-smoke halogen free and non-smoke no halogenated and three classes of A,B,C.

Application :

XLPE Insulated Cable is laying indoors and outdoors. Able to bear certain traction during installation, but not external mechanical forces. Laying single core cable in magnetic ducts is not allowed.

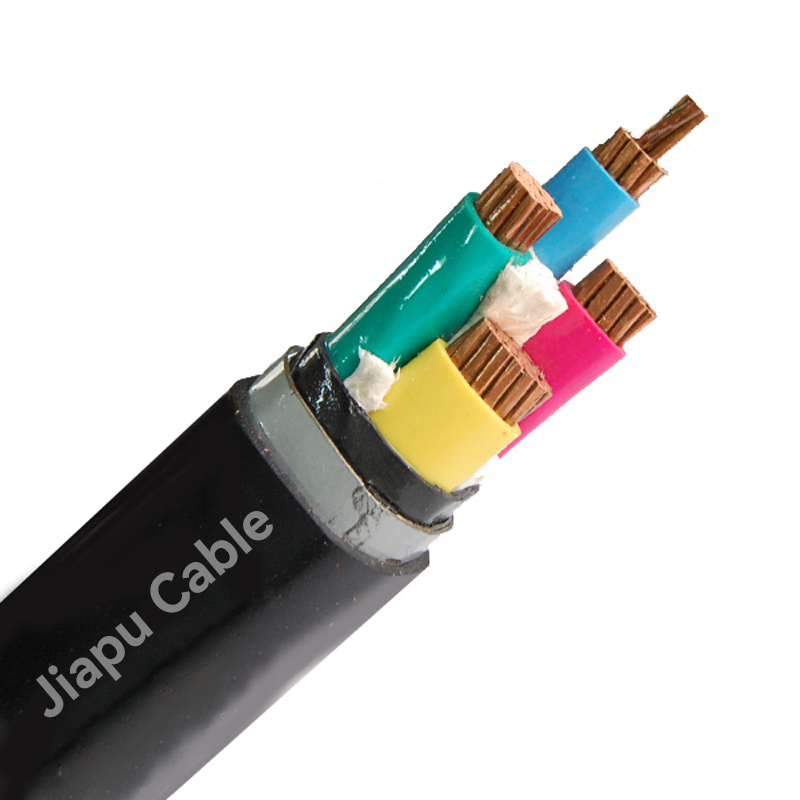

Construction:

Conductor: Class 2 stranded copper conductor or aluminium conductor

Insulation: XLPE

Armour method: Unarmored or Steel Wire Armour (SWA), Steel Tape Armour (STA), Aluminium Wire Armour (AWA), Aluminium Tape Armour (ATA)

Outer sheath: PVC (polyvinyl chloride), or rodent and termite-resistant PVC (optional)

Characteristics :

Rated voltage: 600/1000V

Rated temperature: 0°C to +90°C

Bending radius: 1.5mm² to 16mm²: 6 x outer diameter

25mm² and above: 8 x outer diameter

Fire resistance: IEC 60332 Part 1, BS4066 Part 1

Core color:

1 core: brown

2 cores: brown, blue

3 cores: brown, black and grey

4 cores: brown, black, gray and blue

5 cores: brown, black, gray, blue and green/yellow

600/1000 V-Two core copper conductor xlpe insulated swa pvc sheathed cables

600/1000 V-Two core copper conductor xlpe insulated swa pvc sheathed cables (CU/XLPE/PVC/SWA/PVC)

| Nominal area of conductor | Maximum conductor resistance at 20°c | Thickness of insulation | Thickness of extruded bedding | Dia. Of armour wire | Thickness of outer sheath | Approx.overall diameter | Approx.cable weight |

| mm² | Ω/km | mm | mm | mm | mm | mm | kg/km |

| 1.5* | 12.1 | 0.7 | 1 | 0.9 | 1.8 | 14.2 | 355 |

| 1.5 | 12.1 | 0.7 | 1 | 0.9 | 1.8 | 14.6 | 370 |

| 2.5* | 7.41 | 0.7 | 1 | 0.9 | 1.8 | 15 | 400 |

| 2.5 | 7.41 | 0.7 | 1 | 0.9 | 1.8 | 15.4 | 415 |

| 4 | 4.61 | 0.7 | 1 | 0.9 | 1.8 | 16.4 | 480 |

| 6 | 3.08 | 0.7 | 1 | 0.9 | 1.8 | 17.6 | 570 |

| 10 | 1.83 | 0.7 | 1 | 1.25 | 1.8 | 20.3 | 820 |

| 16 | 1.15 | 0.7 | 1 | 1.25 | 1.8 | 22.3 | 1030 |

| 25 | 0.727 | 0.9 | 1 | 1.6 | 1.8 | 26.3 | 1530 |

| 35 | 0.524 | 0.9 | 1 | 1.6 | 1.8 | 28.5 | 1840 |

| 50 | 0.387 | 1 | 1 | 1.6 | 1.8 | 30.9 | 2070 |

| 70 | 0.268 | 1.1 | 1 | 1.6 | 2 | 34.9 | 2670 |

| 95 | 0.193 | 1.1 | 1.2 | 2 | 2.1 | 40.1 | 3660 |

| 120 | 0.153 | 1.2 | 1.2 | 2 | 2.2 | 43.7 | 4350 |

| 150 | 0.124 | 1.4 | 1.2 | 2 | 2.3 | 47.5 | 5160 |

| 185 | 0.0991 | 1.6 | 1.4 | 2.5 | 2.5 | 53.3 | 6600 |

| 240 | 0.0754 | 1.7 | 1.4 | 2.5 | 2.7 | 59.1 | 8100 |

| 300 | 0.0601 | 1.8 | 1.6 | 2.5 | 2.8 | 64.1 | 9660 |

| 400 | 0.047 | 2 | 1.6 | 2.5 | 3.1 | 71.3 | 12000 |

| 500 | 0.0366 | 2.2 | 1.6 | 3.15 | 3.3 | 79.8 | 15500 |

*Circular solid conductors (Class 1).

All other conductors Circular stranded or circular stranded compacted (Class 2).

Cables conform to BS 5467 and generally to IEC 60502 – 1.

600/1000V-Three core copper conductor xlpe insulated swa pvc sheathed cables (CU/XLPE/PVC/SWA/PVC)

| Nominal area of conductor | Maximum conductor resistance at 20°c | Thickness of insulation | Thickness of bedding | Dia. Of armour wire | Thickness of outer sheath | Approx.overall diameter | Approx.cable weight | |||

| Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | |||||

| mm² | Ω/km | mm | mm | mm | mm | mm | kg/km | |||

| 1.5* | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.3 | – | 330 | – |

| 1.5 | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.7 | – | 350 | – |

| 2.5* | 7.41 | 0.7 | 0.8 | – | 0.9 | 1.4 | 14.4 | – | 390 | – |

| 2.5 | 7.41 | 0.7 | 0.8 | 0.9 | 1.4 | 14.8 | – | 415 | – | |

| 4 | 4.61 | 0.7 | 0.8 | – | 0.9 | 1.4 | 15.9 | – | 490 | – |

| 6 | 3.08 | 0.7 | 0.8 | – | 0.9 | 1.4 | 17.2 | – | 580 | – |

| 10 | 1.83 | 0.7 | 0.8 | – | 1.25 | 1.5 | 19.6 | – | 850 | – |

| 16 | 1.15 | 0.7 | 0.8 | – | 1.25 | 1.6 | 22.2 | – | 1110 | – |

| 25 | 0.727 | 0.9 | 1 | 0.8 | 1.6 | 1.7 | 24.3 | 23.2 | 1520 | 1420 |

| 35 | 0.524 | 0.9 | 1 | 0.8 | 1.6 | 1.8 | 26.9 | 25.8 | 1910 | 1790 |

| 50 | 0.387 | 1 | 1 | 0.8 | 1.6 | 1.8 | 30.1 | 29 | 2400 | 2250 |

| 70 | 0.268 | 1.1 | 1 | 0.8 | 1.6 | 1.9 | 32.8 | 31.7 | 3100 | 2950 |

| 95 | 0.193 | 1.1 | 1.2 | 0.8 | 2 | 2.1 | 38.2 | 36.7 | 4310 | 4060 |

| 120 | 0.153 | 1.2 | 1.2 | 0.8 | 2 | 2.2 | 41.8 | 40.3 | 5170 | 4920 |

| 150 | 0.124 | 1.4 | 1.4 | 0.8 | 2.5 | 2.3 | 46.4 | 44.5 | 6620 | 6290 |

| 185 | 0.0991 | 1.6 | 1.4 | 0.8 | 2.5 | 2.4 | 50.8 | 48.9 | 7860 | 7510 |

| 240 | 0.0754 | 1.7 | 1.4 | 0.8 | 2.5 | 2.6 | 56.9 | 55 | 9810 | 9410 |

| 300 | 0.0601 | 1.8 | 1.6 | 0.8 | 2.5 | 2.7 | 61.8 | 59.5 | 11910 | 11430 |

| 400 | 0.047 | 2 | 1.6 | 0.8 | 2.5 | 2.9 | 69.2 | 66.9 | 14910 | 14330 |

*Circular solid conductors (Class 1).

Conductors including 16sqmm circular stranded (Class 2).

25sqmm and above shaped stranded conductors(Class 2)

Cables conform to BS 5467 and generally to IEC 60502-1.

600/1000V-Four core copper conductor xlpe insulated pvc sheathed cables (CU/XLPE/PVC/SWA/PVC)

| Nominal area of conductor | Maximum conductor resistance at 20°c | Thickness of insulation | Thickness of bedding | Dia. Of armour wire | Thickness of outer sheath | Approx.overall diameter | Approx.cable weight | |||

| Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | |||||

| mm² | Ω/km | mm | mm | mm | mm | mm | kg/km | |||

| 1.5* | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.3 | – | 330 | – |

| 1.5 | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.7 | – | 350 | – |

| 2.5* | 7.41 | 0.7 | 0.8 | – | 0.9 | 1.4 | 14.4 | – | 390 | – |

| 2.5 | 7.41 | 0.7 | 0.8 | 0.9 | 1.4 | 14.8 | – | 415 | – | |

| 4 | 4.61 | 0.7 | 0.8 | – | 0.9 | 1.4 | 15.9 | – | 490 | – |

| 6 | 3.08 | 0.7 | 0.8 | – | 0.9 | 1.4 | 17.2 | – | 580 | – |

| 10 | 1.83 | 0.7 | 0.8 | – | 1.25 | 1.5 | 19.6 | – | 850 | – |

| 16 | 1.15 | 0.7 | 0.8 | – | 1.25 | 1.6 | 22.2 | – | 1110 | – |

| 25 | 0.727 | 0.9 | 1 | 0.8 | 1.6 | 1.7 | 24.3 | 23.2 | 1520 | 1420 |

| 35 | 0.524 | 0.9 | 1 | 0.8 | 1.6 | 1.8 | 26.9 | 25.8 | 1910 | 1790 |

| 50 | 0.387 | 1 | 1 | 0.8 | 1.6 | 1.8 | 30.1 | 29 | 2400 | 2250 |

| 70 | 0.268 | 1.1 | 1 | 0.8 | 1.6 | 1.9 | 32.8 | 31.7 | 3100 | 2950 |

| 95 | 0.193 | 1.1 | 1.2 | 0.8 | 2 | 2.1 | 38.2 | 36.7 | 4310 | 4060 |

| 120 | 0.153 | 1.2 | 1.2 | 0.8 | 2 | 2.2 | 41.8 | 40.3 | 5170 | 4920 |

| 150 | 0.124 | 1.4 | 1.4 | 0.8 | 2.5 | 2.3 | 46.4 | 44.5 | 6620 | 6290 |

| 185 | 0.0991 | 1.6 | 1.4 | 0.8 | 2.5 | 2.4 | 50.8 | 48.9 | 7860 | 7510 |

| 240 | 0.0754 | 1.7 | 1.4 | 0.8 | 2.5 | 2.6 | 56.9 | 55 | 9810 | 9410 |

| 300 | 0.0601 | 1.8 | 1.6 | 0.8 | 2.5 | 2.7 | 61.8 | 59.5 | 11910 | 11430 |

| 400 | 0.047 | 2 | 1.6 | 0.8 | 2.5 | 2.9 | 69.2 | 66.9 | 14910 | 14330 |

*All conductors shaped stranded(Class 2)

Cables conform to IEC 60502-1

Drum size given above are for cables with extruded bedding

More Product

Send An Email

Send An Email