Suitable for energy networks such as power stations. For installation in ducts, underground and outdoor. Please note: Red outer sheath can be prone to fading when exposed to UV rays.

Standards:

Flame propagation to BS EN60332

BS6622

IEC 60502

Characteristics :

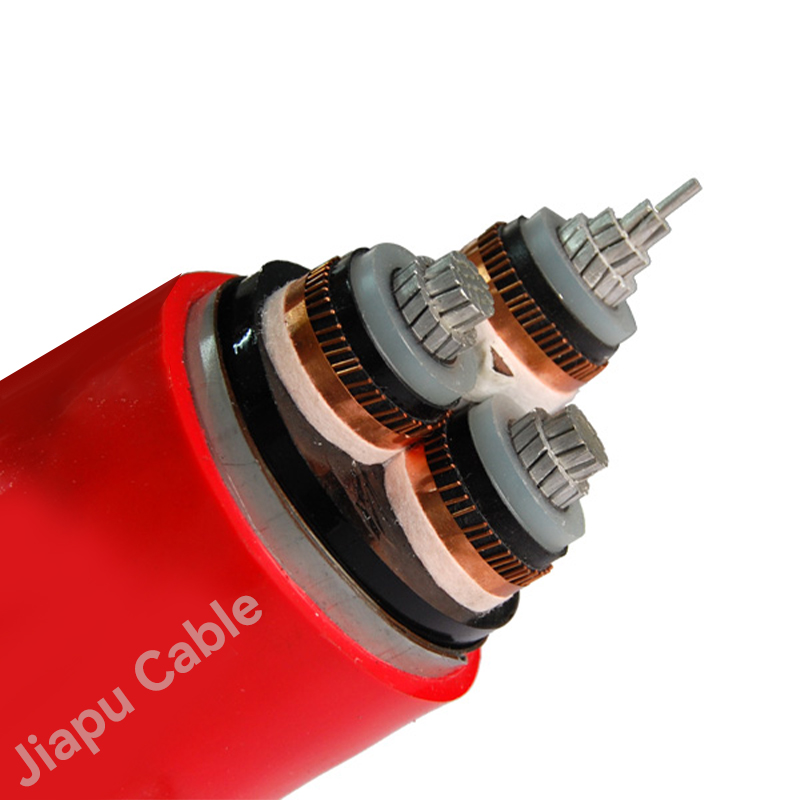

Conductor: stranded plain annealed circular compacted copper conductors or aluminium conductor

Insulation: cross link polyethylene (XLPE)

Metallic Screen: individual or overall copper tape screen

Separator: copper tape with 10% overlap

Bedding: polyvinyl chloride (PVC)

Armouring: Steel Wire Armour (SWA), Steel Tape Armour (STA), Aluminium Wire Armour (AWA), Aluminium Tape Armour (ATA)

Sheath: PVC outer sheath

Sheath colour: Red or Black

Electrical data:

Maximum conductor operating temperature: 90°C

Maximum screen operating temperature: 80°C

Maximum conductor temperature during S.C: 250°C

Laying conditions at trefoil formation are as below:

Soil thermal resistivity: 120˚C. Cm/Watt

Burial depth: 0.5m

Ground temperature: 15°C

Air temperature: 25°C

Frequency: 50Hz

| Nominal area of conductor | Maximum conductor resistance at 20 ℃ | Thickness of xlpe insulation | Thickness of copper tape | Thickness of extruded bedding | Dia of armour wire | Thickness of outer sheath | Approx. Overall diameter | Approx. Cable weight |

| mm² | Ω/km | mm | mm | mm | mm | mm | mm | kg/km |

| 50 | 0.387 | 8 | 0.075 | 1.2 | 2 | 2.2 | 39.4 | 2050 |

| 70 | 0.268 | 8 | 0.075 | 1.2 | 2 | 2.2 | 41 | 2330 |

| 95 | 0.193 | 8 | 0.075 | 1.2 | 2 | 2.3 | 43.1 | 2710 |

| 120 | 0.153 | 8 | 0.075 | 1.2 | 2 | 2.3 | 44.6 | 3020 |

| 150 | 0.124 | 8 | 0.075 | 1.3 | 2.5 | 2.4 | 47.4 | 3570 |

| 185 | 0.0991 | 8 | 0.075 | 1.3 | 2.5 | 2.5 | 49.2 | 3990 |

| 240 | 0.0754 | 8 | 0.075 | 1.3 | 2.5 | 2.5 | 51.7 | 4670 |

| 300 | 0.0601 | 8 | 0.075 | 1.4 | 2.5 | 2.6 | 54.1 | 5410 |

| 400 | 0.047 | 8 | 0.075 | 1.4 | 2.5 | 2.7 | 57.2 | 6430 |

| 500 | 0.0366 | 8 | 0.075 | 1.5 | 2.5 | 2.8 | 60.6 | 7620 |

| 630 | 0.0283 | 8 | 0.075 | 1.6 | 2.5 | 2.9 | 64.8 | 8935 |

19/33kV-Three cores copper conductor XLPE insulated copper tape screened galvanized steel wire armoured PVC sheathed cables

| Nominal area of conductor | Maximum conductor resistance at 20 ℃ | Thickness of xlpe insulation | Thickness of copper tape | Thickness of extruded bedding | Dia of armour wire | Thickness of outer sheath | Approx. Overall diameter | Approx. Cable weight |

| mm² | Ω/km | mm | mm | mm | mm | mm | mm | kg/km |

| 50 | 0.387 | 8 | 0.075 | 1.8 | 3.15 | 3.4 | 78.8 | 9230 |

| 70 | 0.268 | 8 | 0.075 | 1.8 | 3.15 | 3.5 | 82.5 | 10310 |

| 95 | 0.193 | 8 | 0.075 | 1.9 | 3.15 | 3.6 | 87 | 11640 |

| 120 | 0.153 | 8 | 0.075 | 2 | 3.15 | 3.7 | 90.6 | 12850 |

| 150 | 0.124 | 8 | 0.075 | 2 | 3.15 | 3.8 | 93.8 | 14150 |

| 185 | 0.0991 | 8 | 0.075 | 2.1 | 3.15 | 4 | 97.9 | 15700 |

| 240 | 0.0754 | 8 | 0.075 | 2.2 | 3.15 | 4.1 | 104 | 18120 |

| 300 | 0.0601 | 8 | 0.075 | 2.3 | 3.15 | 4.3 | 109 | 20570 |

More Product

Send

A

Email

Send

A

Email